Practiced a few down turns again and actually was able to slide across the grass whilst being pulled and stayed on my feet.

Things are going ok with practicing so far, next i have to be able to launch on my own , so i think that will be the next stage, landing is not a worry..

Ive been getting the gear together for a vacuum table. So far the pump, a fair bit of old lpg gas hose and fittings, a large syringe ( cant get the carby part yet.)

I have been thinking about the PBT sheet that goes on the boards for the shine finnish. I have seen how every ones that makes a board by vacuum bagging gets a great shine on the bottom and at times a crinkly finish on the top. Got me to thinking.

Ive read how people make the boards in two part. They laminate the base and at times later on laminate the top at a different time.

So, considering the bottom comes out slick and shined because it's on the perspex sheet how about if you turned the board over once the top was done and laminate the top as you did the bottom.

Maybe the pics will explain better.

| |

| Normal Rocker Table Setup |

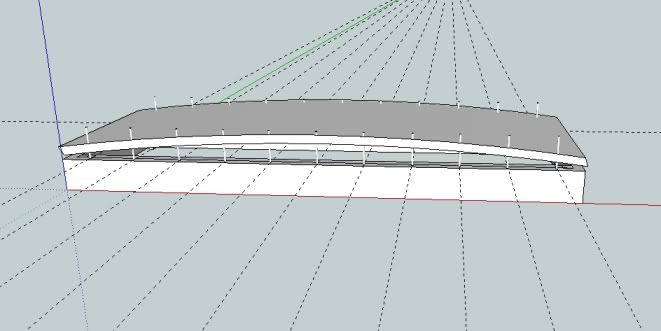

So we adjust the rocker like this. Turn over the board with the completed base and lay it up in this position with the top facing down.

| ||

| Inverted table top |

Maybe i am right , could be wrong, but hey worth a thought. The drawings were done in Google sketch up pro.

Hey Peter

ReplyDeleteGreat job blogging. The blogs I enjoy the most are ones that documents nitty gritty of someones learning. It makes for a powerful learning tool for anyone interested in the same stuff.

This shine off the table really is a tricky one. I think that the invertable rocker table does have some real potential and worth developing the idea some more. The big challenge I see is how you get concave in the table surface when its inverted. I guess if you have a row of adjusters down the middle that can both push and pull the center line to form your rocker then that may well work. if you have a 3-D surface on top, anything where there will be a gap between the table and the surface fo the board then under vacuum it may bend. I'm thinking particularly of the area near the rails. Maybe you could lay down some thickish rubber or really dense foam rubber to support it when its upside down.

Another approach which I'm thinking of trying is to use perforated release film instead of peel ply. Release film is plastic film with different perforation patterns. It allows some excess resin to be removed but nowhere near as much as peel ply which is woven (dacron I think) material. You just need to make sure you don't start out with too much resin cause you'll end up with the excess resin trapped in the glass and so you get a weaker end product.

Have you seen the BroKite videos? http://brokite.com/ Good for a laugh and very innovative!!!

Thanks Matt. I also wanted something to look back on like a diary i guess and see what i went through. We lose so many things that we think we should have noted. Then when it's too late we think about jotting something down

ReplyDeleteI did not even think of the concave being reversed, good point. That just would not work. Now you've just given me something else to think about all day, what is it with this sport and im not even on a board yet, lmao.

Im going to model the table on the squirtnatic type linked on your blog by downunder. It has a thin table top but it would still be interesting pulling it "down" in reverse.

I ohnestly dont think i will put a concave in the first couple i do, they will be just to get me going.

I guess that is where the pre made top sheets would be the solution.

I watched the brokite stuff a while back, its very basic what they are doing in reality. You know, if the PBT was readily available here there would not be alot of difference between the finnish they have and yours. I am sure it is here but under a different name. It's just a matter of finding it....

Hmm 50kmh winds tonight, no trainer for me.

cheers take care, thanks for reading :-)

Hey Peter,

ReplyDeleteHere's some more detail on the 'pre-cured' approach.

http://www.kiteforum.com/viewtopic.php?f=107&t=2374292

I do really like the idea of the table you designed. I have played around with idea's like that myself. One of the great benefits of it is that you could put channels in the bottom of the board vac bag it which you can't do with my setup. I was thinking maybe the table surface could have perspex glued over MDF so the screws could go through the MDF and be coverd by the perspex. If you used contact adhesive there might be enough give in the glue to reduce the force needed to pull the convex surface into it.

Food for thought anyhow.

Cheers

Matt